Deep drawing is a very popular method for the production of cups, box-shaped and other complex hollow products. Most design engineers have learned how to design a part for milling or turning, but designing for deep drawing requires a different view and way of thinking. Deep drawing belongs to sheet metal techniques like bending, cutting, hydroforming, roll forming, spinning, stretching and stamping

Fabrication differences between deep drawing and machining.

In essence, the biggest difference is the fact that with machining material is removed and with deep drawing material is deformed. Understanding these two differences is the key to designing a successful deep-drawn part. Below a section view of the starting material and the result for both machining and deep drawing.

|

|

|

| With machining the process is aimed at tools that can remove material in an efficient and precise manner, so the leftover is the requested product. | With deep drawing, you start with a flat sheet (called blank) and deform this sheet to a hollow 3d shape. The sheet is cold-formed which means molecules are being displaced in the sheet. |

Key differences between deep drawing and machining

Due to the different technologies, you have to think about the possibilities and disadvantages these techniques give you. See also this article for more information between the different techniques. Below a short summary of the key differences

| Deep drawing | Machining | ||

| Different wall thickness | In essence, the wall thickness is equal to the start sheet, but this can be reduced to a certain level in the process | No limitation in creating multiple thicknesses | |

| Thin walls | Very thin walls possible down to 20 micron. | wall thickness below 0,2mm is challenging if not impossible. Caused by the mechanical forces applied to the product during machining | |

| Strength and weight | Deep drawing gives a high strength since the material hardens during the process. In general, products can be lighter and stronger compared to machining | The strength of the material doesn’t change during the process. Hardness depends on what can be machined easily. Normally heavier than deep-drawn parts | |

| Quantities | Very scalable. Used for high volumes, but can be interesting already from 10 pcs | Very suitable for prototyping and small series |

Basis rules designing a product for deep drawing.

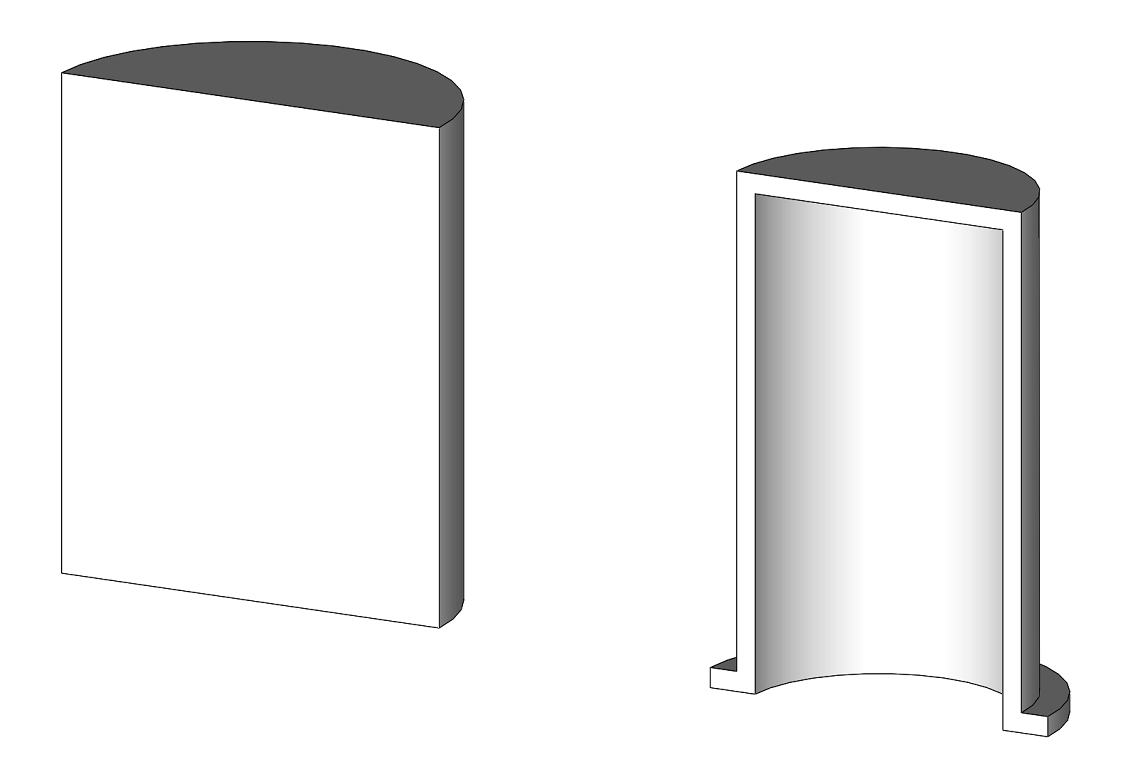

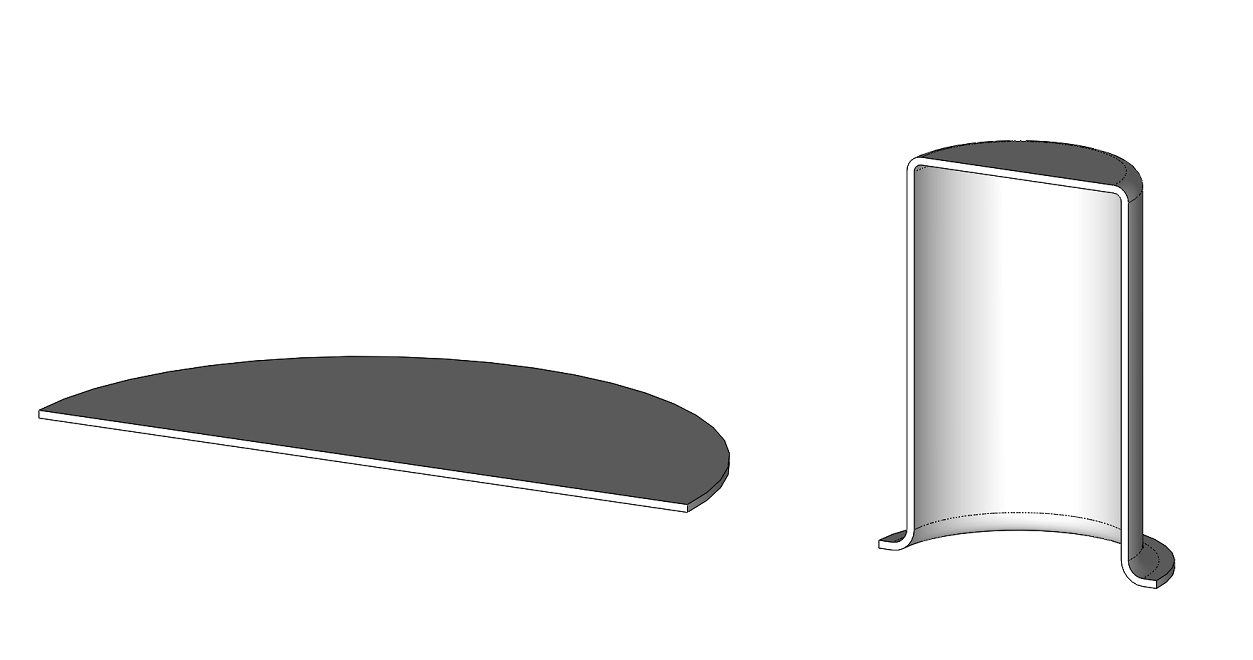

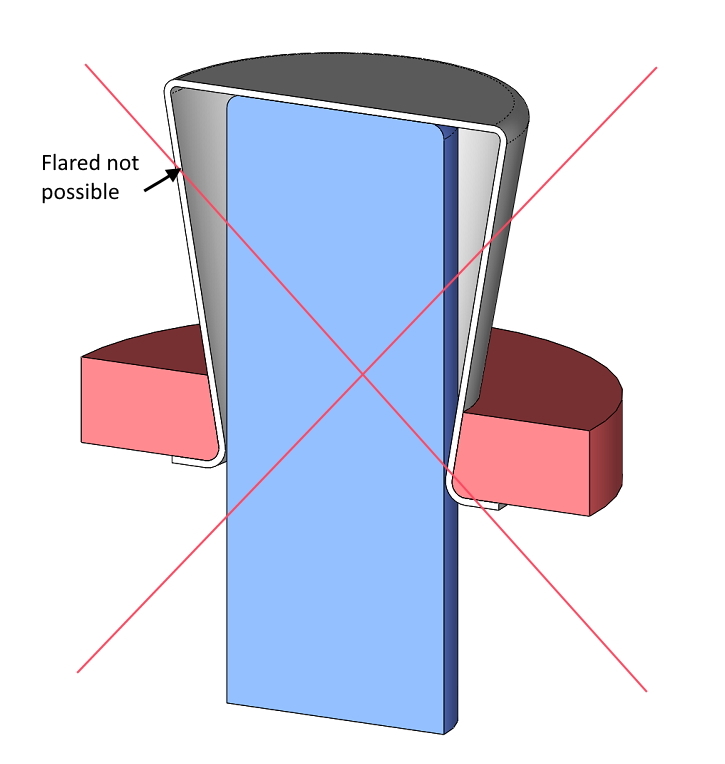

1) Tapered products

Products that are flared to the outside are in general not possible to deep draw. The punch basically has the dimensions of the inner dimensions of the die minus the thickness of the material, it cannot draft outwards. Next to the fact the punch cannot press the material to the outside, it is also not possible to release the product from the die in this way. Sometimes there are other techniques and processes possible to make these kinds of parts like for example hydroforming. Please contact us to explore the possibilities if you have complex shaped parts.

|

|

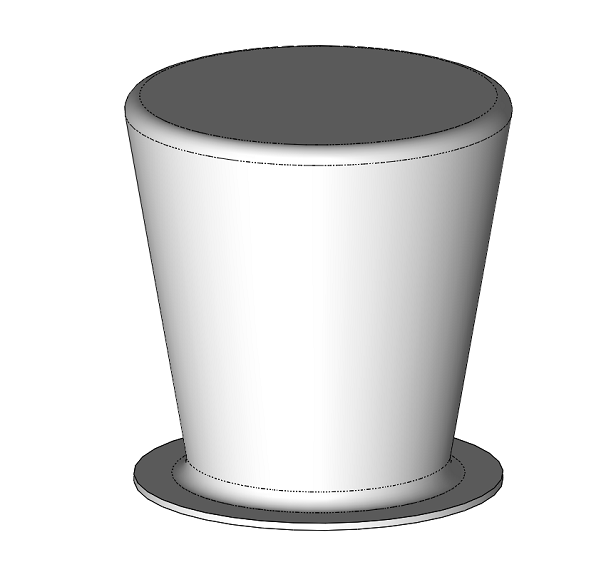

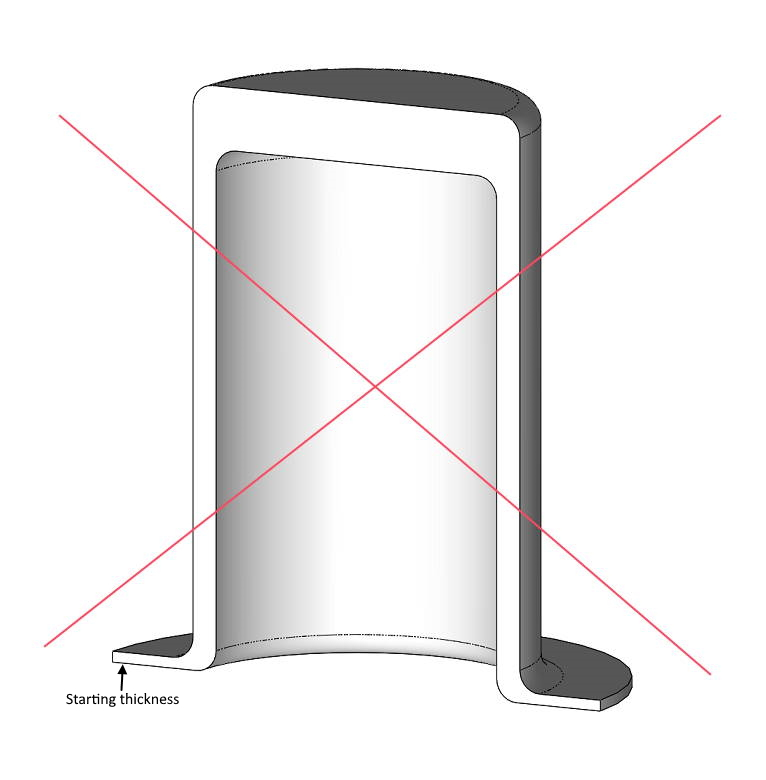

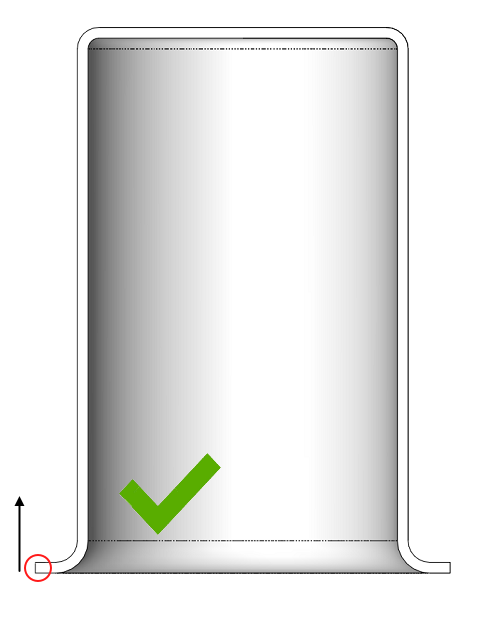

2) Products with walls thicker than the starting material

Products with walls thicker than the starting material (blank) are not possible to make with deep drawing (left). Sometimes there are some other possibilities to make the part. This process is called ironing. You start with a thicker part and stretch the walls in the length and in this way thin the walls while the bottom stays thick. Ask us for the possibilities

|

|

3) Cutting the flange

Vertical cuts are in basic easier to make because they are in line with the press direction. Perpendicular cuts to the wall are possible but have more wear on tooling or they can be cut with complementary techniques like laser cutting. Both are costs increasing.

|

|

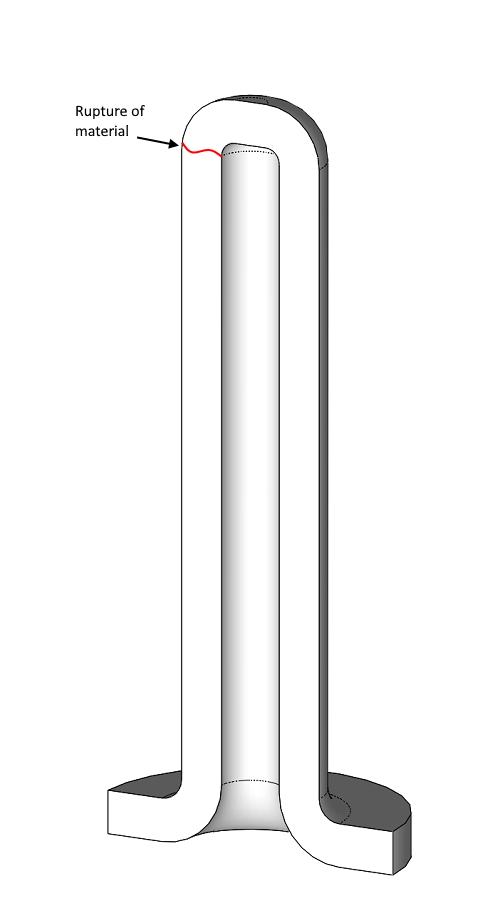

4) Ratio between diameter and material thickness

Products with a very low diameter - wall thickness ratio are not possible to draw. Due to the high force which is needed to draw the material into the die, the bottom will rupture because it will go over its tensile strength. If a small diameter is required, it is best to also decrease the thickness of the base material so the walls will be thinner.

|

This are some examples to take into account when designing a deep draw product. For more information about deep drawing see this article or go to the main section for more information.

If you want to know if your application is suitable for deep drawing, please contact us or sent an email to This email address is being protected from spambots. You need JavaScript enabled to view it..